Assembly technologies for flexible or semi-rigid materials have remained unchanged for many years regarding hotmelt, calendering & flat bonding technologies. However, Rovitex has invested in a complementary process that respects the environment: ULTRASONIC assembly.

Rovitex is also integrated for control, cutting.

Lamination by calendering

Multi-layer assembly. This line has been designed for the continuous assembly of fabrics, non-wovens, films, paper, mesh with precise temperature control.

Line cut, width 330cm

Flat Lamination

Multi-layer assembly (up to 45 layers), the materials are driven by two Teflon-coated belts without connection and calendered between two cylinders.

Bonding on any type of flexible or rigid support, of different thicknesses using glue in different forms (film, web, grid of different natures). Precise temperature control (heating zone with 18 independent zones & integrated cooling zone) allows perfect control of the assembly.

Line cut, 220cm width

Hotmelt lamination

Assembly with PUR glues on all types of materials (mesh, warp & weft, membranes, films, non-woven, foam, spacer etc.).

To obtain waterproof, windproof, breathable, absorbent.

Width of 220cm.

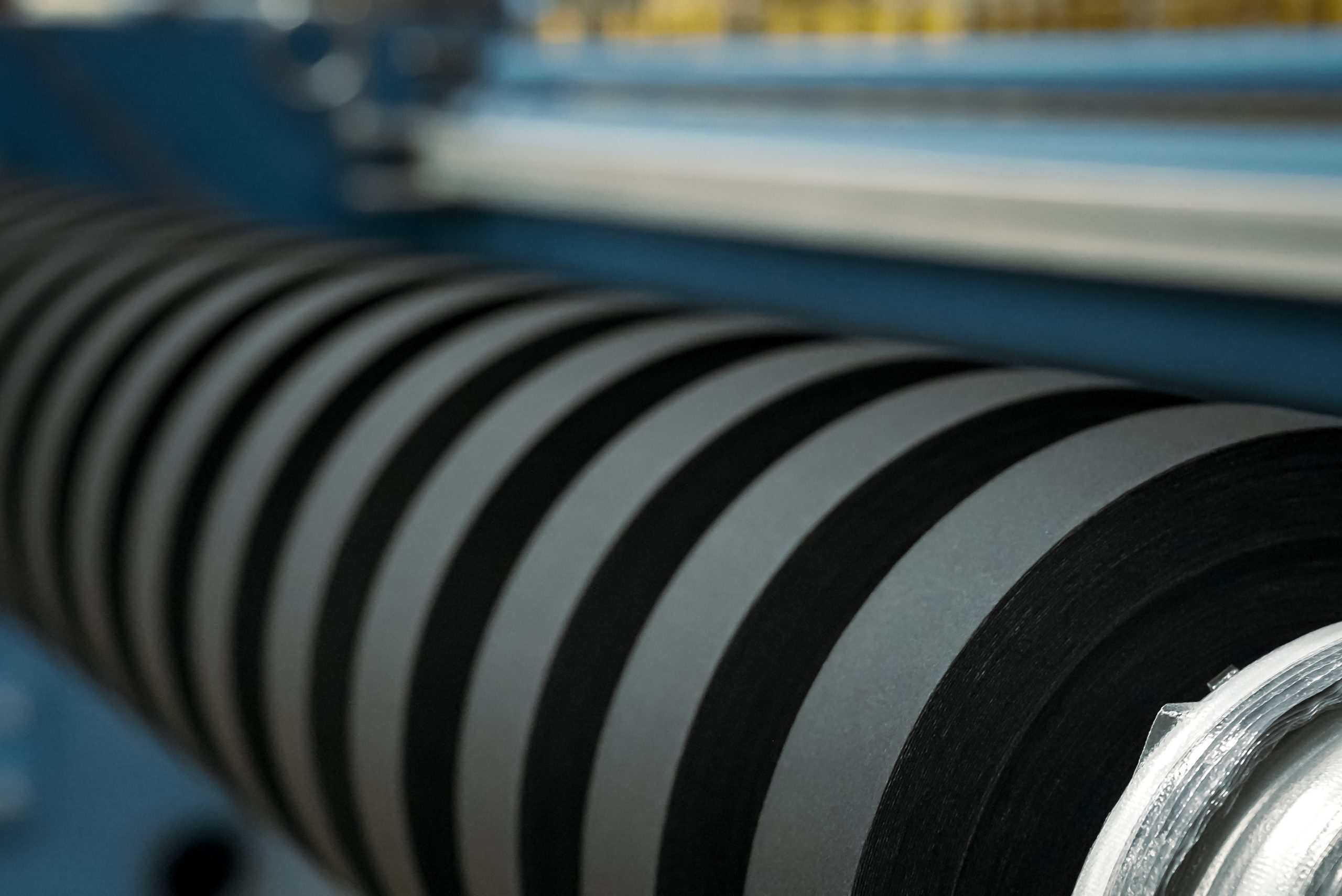

Cutting into strips

Strip cutting by crushing or hot technology depending on the supports.

(1.5cm to 100cm) width 200cm.

ULTRASOUND PADDING

The assembly of materials is made by the fusion of materials through welding caused by pneumatic pressure and ultrasonic vibration.

The design is made by an engraved design where each design needs its own roll, providing an even finish and quilted layers, top fabric + fiberfill + bottom fabric or lining, permanently sealed. Cylinders or rollers offer the most varied drawing possibilities, in geometric or artistic forms. Width 240cm

INSPECTION

- 100% stickiness control

- elimination of defects according to customer specifications

- possibility of high speeds

- specific roll packaging

The complexes are unwound on a lighted table with low speed and are packaged at the outlet.